DH-4M2

DH-4 Mail plane in the movie

“Spirit of St. Louis”

One of Robertson’s DH-4s

Original DH-4M2

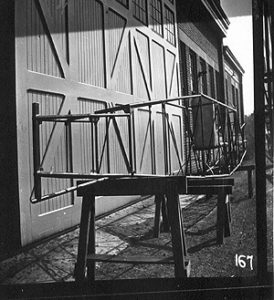

Project as received

The DH-4 was the only U.S. manufactured aircraft to engage in combat in WW I. With the 400hp Liberty engine (the most powerful engine of its time) and a wing span of 42 1/2 feet and 30 feet long it could perform quite well at a gross weight of 4400 pounds and cruising speed of 125 MPH at sea level. Lightly loaded it was faster than the German fighters of the time, right up to the closing days of the war. It was produced in greater numbers than any other aircraft. When the production was terminated in March 1919, a total of 4,846 had been built. Due to its excellent performance and “always being there”, it dominated the post war service until the late 1920’s. In 1920, a steel tube fuselage was created using the other parts of the DH-4B. The steel fuselages were safer and were in service as late as 1932. Boeing Company built 180 DH-4M-1s and later another 150, while Fokker American’s Atlantic Aircraft Corp. built 130 DH-4M-2s. The M-2 fuselage is made of larger, heavier tubing.

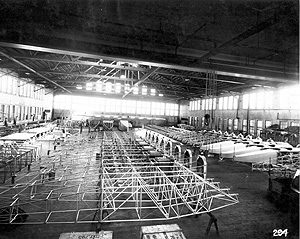

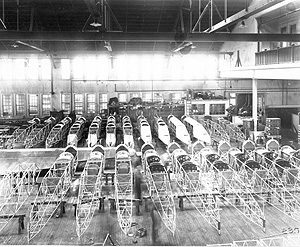

Assembly line at Atlantic Aircraft showing DH-4M2’s and 5 Fokker Tri-motors in the background of the left picture.

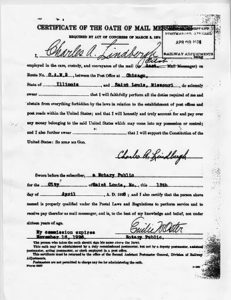

Many DH-4s were used by the Postal Service during the 1920’s, and many of the later ones were M models, after they were released from the military. This unit, being built up for the Historic Aircraft Restoration Museum, is an M-2, and will be converted to a Mail Plane as used by Robertson flying Service on the C. A. M. 2 route between Chicago and St. Louis. Charles Lindbergh was a mail pilot for Robertson, and one of his log book entries refers to a metal DH-4. That particular aircraft was actually an M-1, but the sketchy records still available indicate that Robertson did have a few M-2’s sometime after Lindbergh left the company.

Now on permanent display in the Historic Aircraft Restoration Museum.

DH-4M2 heading for the shop

Old fabric coming off

Liberty engine exposed

On blocks and ready

Flying surfaces ready

Fuselage at the factory 1922

Fuselage at the shop 2004

Top sheet metal fitted

Top cowl nearly finished

Shawn Miller donating his magic hammer to finish the cowl bumps

Single seat mail plane

Front cockpit for rides

Firewall fitted

Ready to set up the engine

Will it fit?

It does!!

Fabricating the manifolds

Manifold pipes finished

Exhaust pipes finished

Fuselage ready for fabric cover

Fabric on aft portion

Final color

Cockpits installed

Time for some side panels

Making the side panels

Panel fitted

Silver is on

Left side

Instrument panel finished

Cockpits are finished

Cross-wind landing gear

New shoes!!!

Pounding louvers on the side cowl

Kenny deburring the louvers

Louvers are cool

RM RMM RRMM RRRMM RRRRMMRRR

Starting the wings

Starting the wings

Wing covered (almost)

Riblacing going on

Brandyn covering an aileron

Brandyn covering the elevators

Finish tapes going on last wing

Wings covered

Attaching the wings to make new brace wires

Pink Wings??? …………..Nah….

Prepping the Wings for Silver

Skyler sanding an aileron

Don sanding another aileron

Wings almost on

Wings installed and rigged

Retractable gear DH-4 ?

Landing gear ready for color paint

Landing gear assembled

Landing gear on and ready to roll

Ready to run

Will it start?

It actually runs!!!!!!!!!!!!!!

All together but unpainted

ROOAARRR!!

Out where it belongs

Not so loud out away from the hangars

Fast taxi test

First flight take off

Here we go!!!!!!!!!!!!!!!!!!!!!

YAHOO!!!!

Sounds like a diesel truck on the highway

That was fun!!!!

The only flyable one in the world!!

John Murray welding the gas tank leak

Final color?

Robertson’s color scheme

First time out of the pattern

Just cruisin’

Wish I had some letters up front

Sounds like a herd of Harleys back there

Even a month later and a new nose paint job the Harleys are still back there

Maybe they will stop at the river

Still back there….OH well

The Dec,1 2006 ice storm glued the hangar doors shut.

More pictures will be added after the ice clears a bit.

Photo crew.

Expert photo pilot Tim, DH-4 tester Glenn, and camera wielder Don

Cockpit view

New modern radiator core being fabricated by Proliance International.

Formerly G&O Mfg.Co., the original manufacturer of the DH-4 radiators.

Ready to ship

Building the tanks

Lining the hole for the prop shaft

Finished ready to install

Back in the air again

I guess it is time to go back to the airport

Al takes a ride

Fly-by

Al (smiling) Stix and Glenn

Test flight by Authentic DeHavilland test pilot Desmond Penrose

Desmond came all the way from England to see this aeroplane.

His smile indicates that his unexpected test flight went well

Now some serious flying. Off to OSHKOSH 2007

First stop for some (a lot) gasoline and a bit of water

It starts easy if the starter would work

Pictures of the repairs to the generator, water pump and re-repair of the starter seem to have been forgotten

The 4 hour trip was made in 4 flights

Sunday, Monday, Tuesday, and Friday

Finally made it to OSH

Well received

THANK YOU ALL !!

If you believed that, well…. then…………………

AirVenture Oshkosh 2007

Judges Choice Award

Wonderful, uneventful trip all the way home

4 hours in 3 flights on the SAME day to get home.

Now if I can land it one more time.

It’s Never the same…

( the pictures might seem so )

Go for a ride

Skyler gets the first ride up front

Don’s ride

You might want to be standing somewhere else

Turning final

Short final

For a short video go to

Flying the Dh-4 Around the Patch

http://www.youtube.com/watch?v=qHCzpzeZDiY&feature=related

Off on another GREAT adventure

2008 Antique Fly-in at Blakesburg, Iowa

Together with best friends

Charles Lindbergh’s Air Mail Pilot Certification

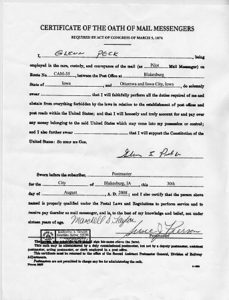

Glenn Peck’s Air Mail Pilot Certification

Flying the U.S. Mail along with the Boeing 40

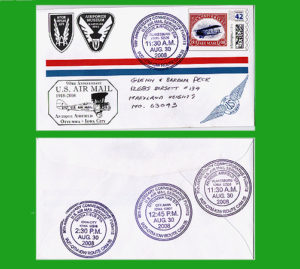

Actual U.S. Mail carried on DH-4 Flight

Antique Airplane Association 2008

Sweepstakes Award

Wonderful article from New Zealand

Lots of memories now